The Future of Australian Manufacturing

The blog post outlines the transformations in the Australian manufacturing industry due to the digital shift, specifically toward Industry 4.0 - characterized by real-time data exchange between sensors and machines. It emphasizes the importance of innovating not only in manufacturing processes, but also in reimagining business models and better understanding customer needs to provide high value solutions. The blog warns against implementing technology for its own sake, reinforcing the idea that the right technologies serve to improve and personalize customer experiences and open new market opportunities.

Last month I learned a lot about manufacturing and Industry 4.0 in Australia. I thought I would use this opportunity to share my observations around National Manufacturing Week. On Monday before National Manufacturing Week opened, the Sheda team and Wrays co-hosted an event at Google Melbourne’s offices on Industry 4.0 and the future of manufacturing. We had a panel of subject matter experts to explore the topic. Industry 4.0 is the newest stage of automation in manufacturing where sensors and machines exchange data in real-time. Manufacturing businesses worldwide are currently transitioning to more digital operations revolving around Industry 4.0, businesses that do not embrace this change may be left behind in this new world. In this post, I’ll share some of my learnings and observations from the last week.

Industry 4.0 Revolution: New trends in smart manufacturing

Our event on “Industry 4.0 Revolution: New trends in smart manufacturing” kicked off with an engaging presentation by Dr Jens Gonnemann Director of the Advanced Manufacturing Growth Centre (AMGC) on transformation of the manufacturing and I gave a quick report on my observations of Hannover Messe, we had a panel discussion on Industry 4.0 and digital transformation of manufacturing.

Jens Goenneman was joined by Vela Georgiev founder of HardworX and Dr Clive Milham, National Technology Advisor of the AiGroup. Some of my takeaways from the panel were

- Digital transformation and Industry 4.0 is not only focused on manufacturing production but will also bring big societal changes with it

- Australia needs to zero in and focus on niches to be successful on the world stage

- High value and low volume production has a future in Australia

- More skills need to be developed around Industry 4.0 and automation

National Manufacturing Week

National Manufacturing Week provided similar topics to Hannover Messe but on a lot smaller scale, where Hannover Messe had 25 halls of manufacturing, National Manufacturing Week had one. There were some fantastic technologies to explore. I got to try out virtual welding by Weld Australia and saw some of the assistance systems that were also presented at the Hannover Messe.

At the Industry 4.0 stage there were lots of insightful talks on the digital transformation of Australian Manufacturing, Jens Goennemann hosted a panel of Innovators in the manufacturing industry. Shortly after, Mark Goodsell from the Ai Group talked about how digitalisation leads to business model transformation via skills and people, in his words

“Math and science are not enough. We need people to be creative.”

Then A/Prof Nico Adams from Swinburne’s Factory of the Future explained that one of the benefits of the Internet of Things is the possibility of implementing new business model and provided an exciting example of a comedy theatre in Barcelona that charges punters by the number of laughs measured via facial recognition.

There are some excellent Australian organisations that are providing help to Australian manufacturers to transform into a more digital future. The AMGC just launched the Manufacturing Academy. It’s an online platform showcasing the stories of manufacturers on their digital transformation journey. It condenses some of AMGC’s comprehensive transformation knowledge into video modules to assist companies with their digital transformation.

David Chuter and the Innovative Manufacturing CRC (IMCRC) ran a few of their FutureMap workshops at National Manufacturing Week. FutureMap is a tool to help manufacturing SMEs to assess their current state of business and identify areas to transform and future-proof their business. I took part in one of IMCRC’s FutureMap workshops and found the tool very helpful to reflect on your business.

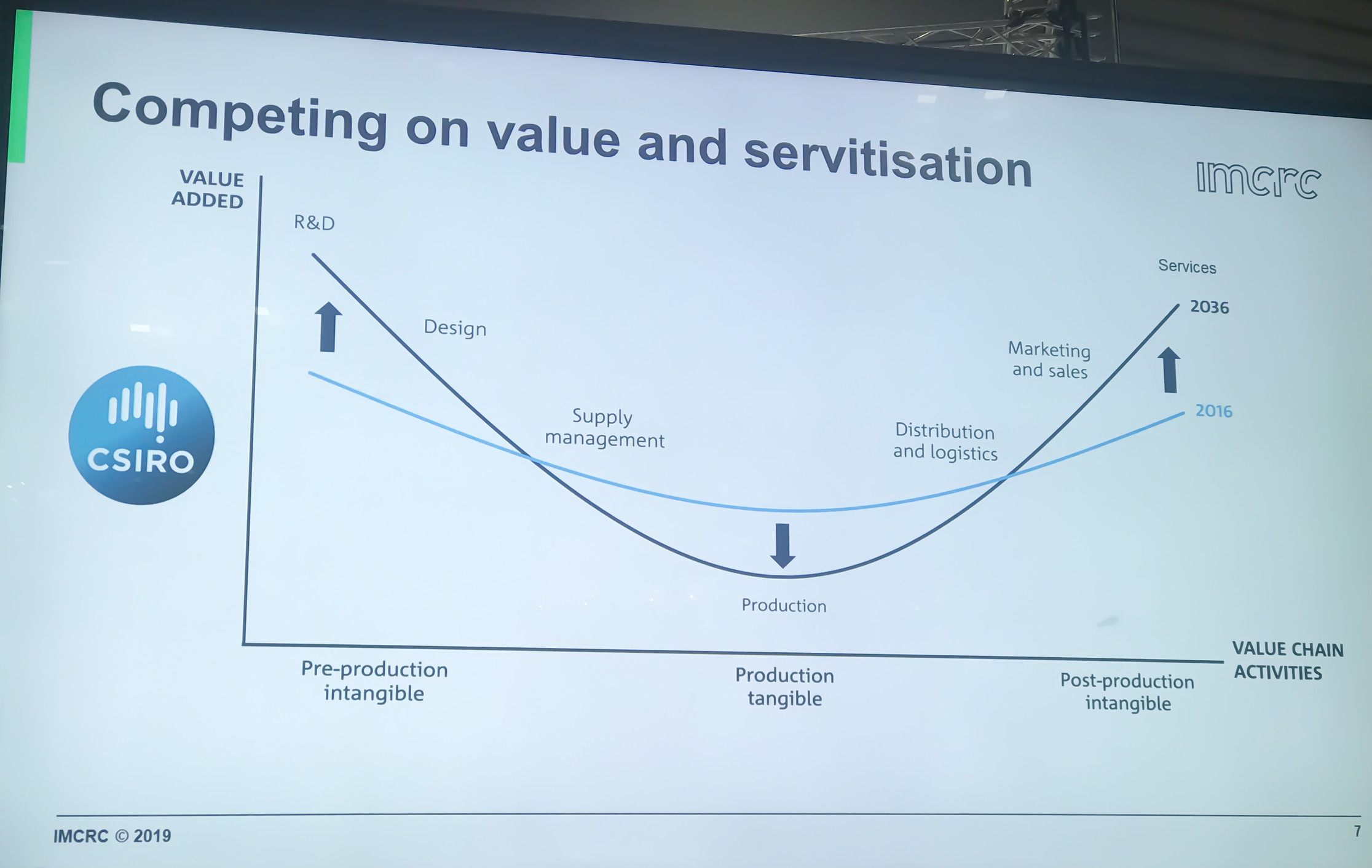

Smiley Curves

One thing that kept reappearing was the so-called “Smiley Curve”. The Smile Curve basically displays the value chain on the x-axis and the value added on the y-axis. There is more value added on the start of the curve, in R&D and end of the curve in marketing and services. This gives the curve the appearance of a smile.

I have seen this curve in at least 5 slide decks over the conference. From a Human-Centered Design and strategic point of view focusing on R&D, design and delivery of your service and how the product and service is offered is a no brainer. This is because by discovering a clear value proposition through R&D and delivering your value proposition through marketing, sales and customer service, you provide more value for customers and generate a robust and defensible service offering for your business.

How can we use Industry 4.0 to maximise value for customers?

It is important to do research into your customers to figure out what they actually need and want. Using design thinking methods can help to develop a better understanding of your customers and explore new potential customer segments. Digital technologies and IoT allow you to build and test prototypes your customers, listen to their feedback and iterate until you create something that your customers love. It's important to only built products our customers need and want or in the words of Ash Maurya “Life’s too short to build something nobody wants.” Otherwise, you will end with products that don’t generate much value of the customer, like this $400 juicer, for example, that doesn’t do anything your hands couldn’t do.

Business model design

You can innovate on your products and services without even changing the core product, one way of doing this by switching the business model around it. An excellent example is Rolls-Royce who moved from selling air-plane engines to an “engine-as-a-service” modell where is it renting out the engines to airlines, including maintenance and collects data on the engine use.

A new business model may reduce the barrier of customers interacting with you and foster a long term engagement with your customers. If you develop a better understanding of your customers you will be able to respond better to their needs and wants and provide higher value solutions to them.

Digitalisation, Internet of Things and Industry 4.0 as enablers

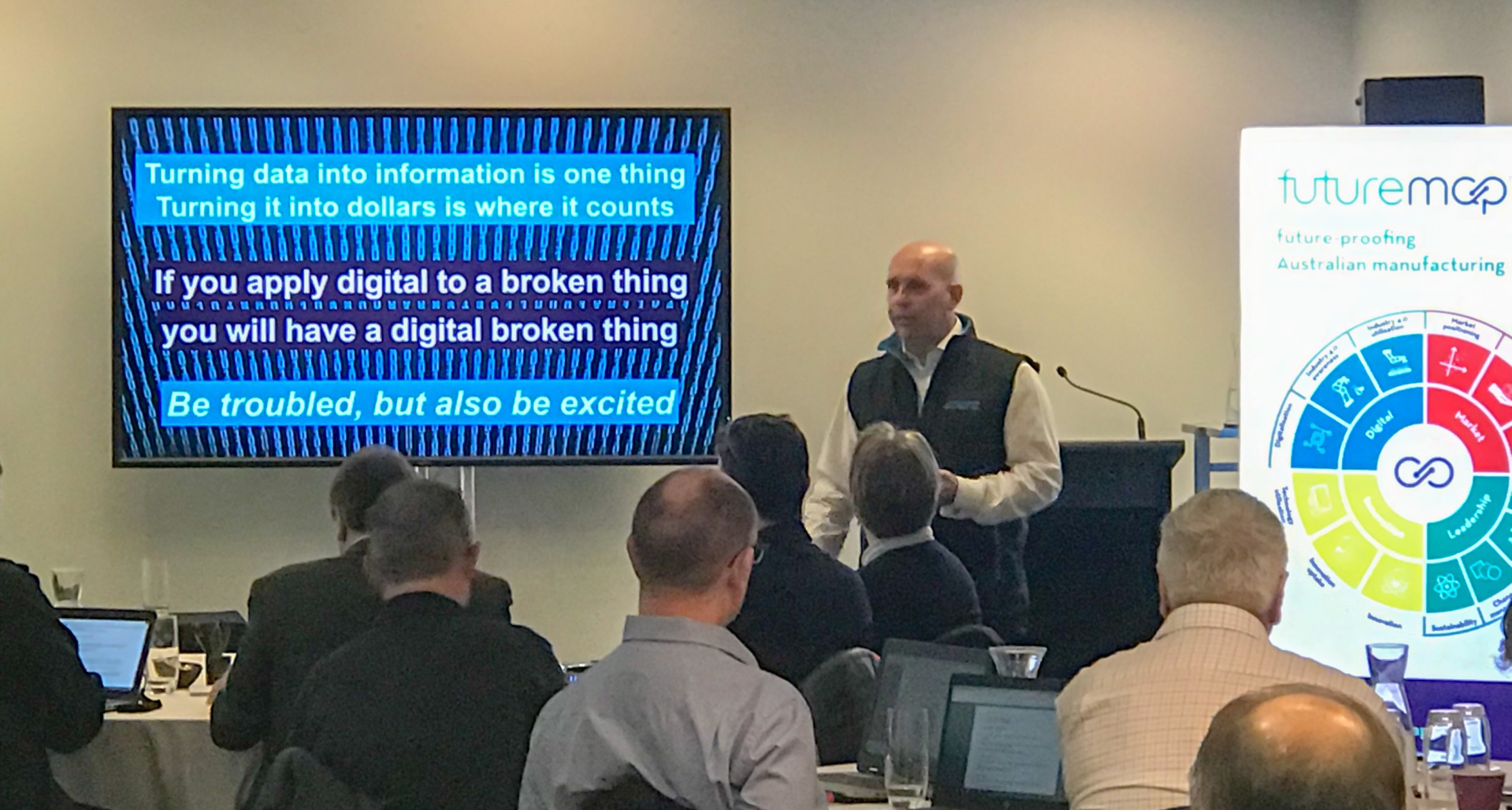

While there were a lot of technology solutions related to digitalisation, industrial internet of things and Industry 4.0 presented at National Manufacturing Week, it's important to remember, implementing technology solutions doesn’t fix broken products or business processes!!

Implementing technology for technology's sake is like pouring accelerant on a dead piece of wood and expecting a raging fire.

Technology, when leveraged properly, can be an enabler that will allow you:

- to understand your customers by providing detailed information on how your products are being used,

- to provide solutions that are more tailored to your customers' needs and wants and

- to create new business models that resonate with your customers and will open new markets

This was nicely summed up by David Chuter in the FurtureMap workshop: “If you apply digital to a broken thing you will have a digital broken thing”

At Sheda we help traditional manufacturing and product businesses transform their operations through Digitalisation, Industry 4.0 and Human-centred design techniques.

Get in touch, if you like to discover how to leverage design and technology to understand your customers better and create new sustainable business models powered by Industry 4.0. You can book a chat with me here, contact me on LinkedIn, or send me an email eike@sheda.ltd